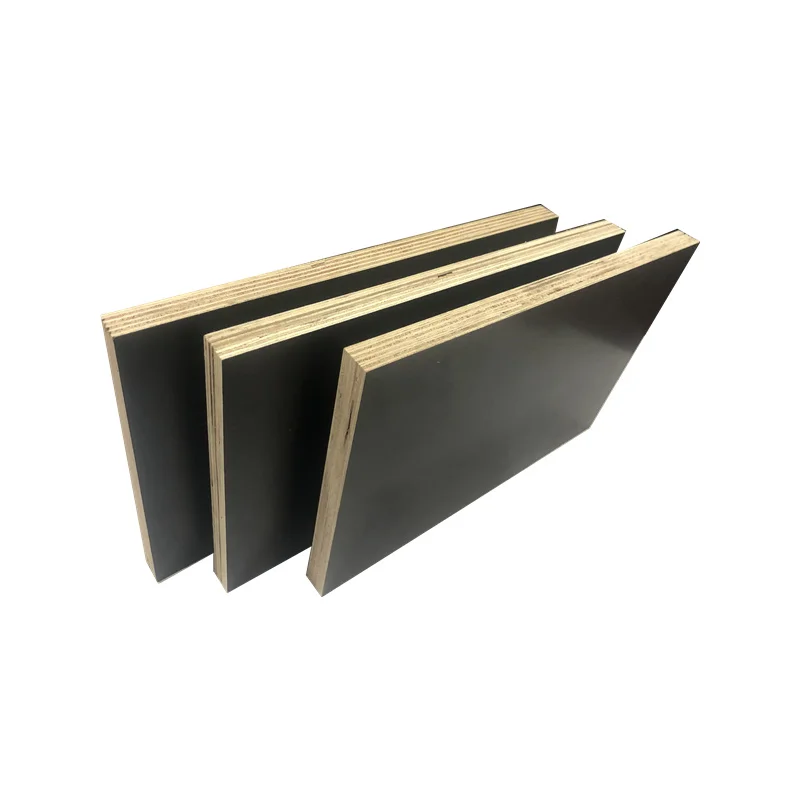

We mainly produce film faced plywood for concrete formwork construction for more than 12 years, having 2 sub-plants, covering an area of 60,000 square meters, and 12 advanced production lines. It can produce a maximum size of high-grade plate,9.6 meters length, 1.5 meters width and 300 mm thickness.

Product Description

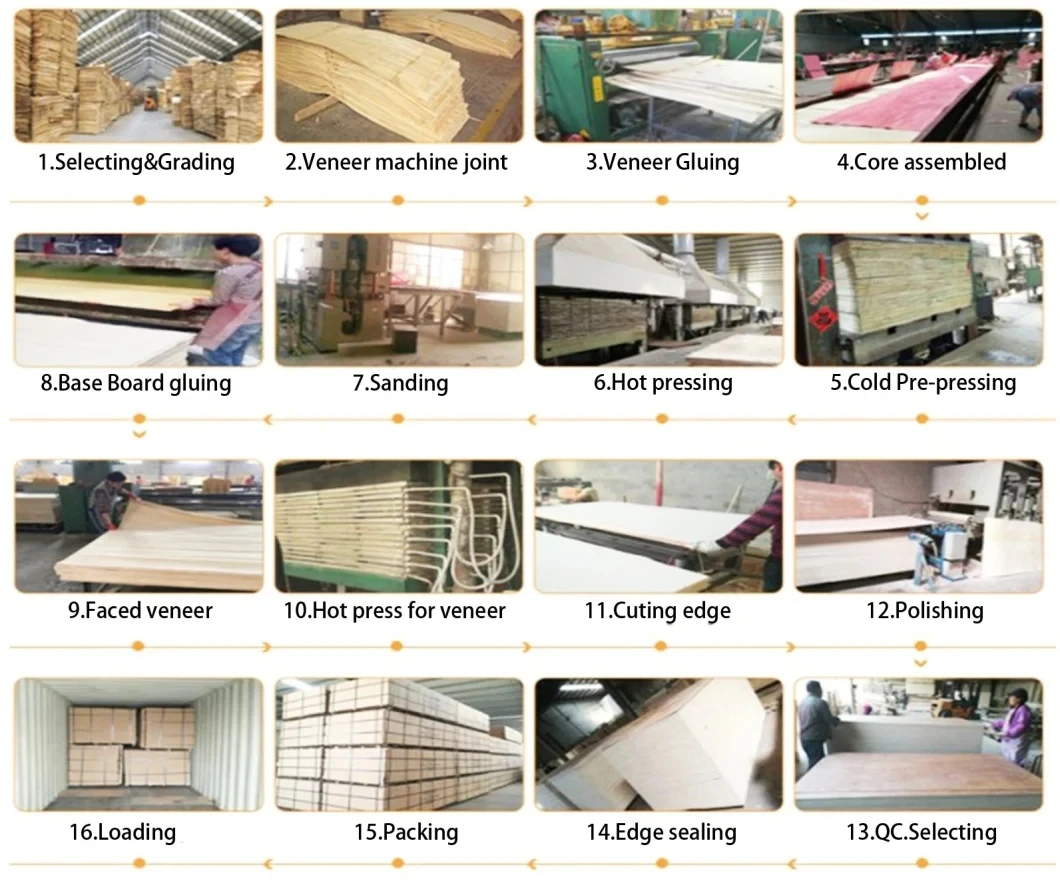

————-PRODUCTION PROCESS————–

IMPORT HIGH-QUALITY WOOD FROM RUSSIA/AFRICA/NEW ZEALAND AND SO ON.

We can guarantee the quality of raw materials. All of our raw wood materials are sourced from high-quality forest production areas at home and abroad, such as Australia, New Zealand, Brazil, and domestic high-quality forest production areas. We will not easily raise the price of products because of the fluctuation of raw materials.AUTOMATIC LOG PEELING PROCESS.

AUTOMATIC LOG PEELING PROCESS.

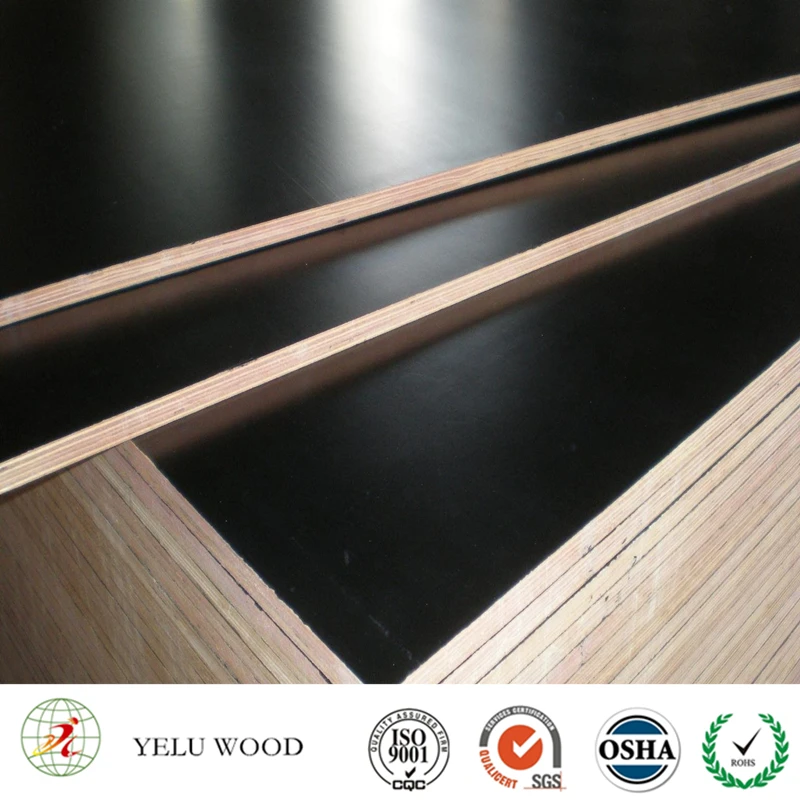

After each log is selected by the saw head and edged, the bark is peeled off by the machine. The peeling is divided into veneer

peeling and core board peeling. Each plywood core board is made of eucalyptus or pine wood, while the veneer is made of pine wood to ensure that each board does not warp, deform, crack, have good water resistance, high turnover rate, and repeated use times.

————–PRODUCT DETAILS—————

Specification

Certifications

Application

FAQ

Q:Where is the factory located?

A:Shandong Yelu Wood Co., Ltd. is located in Ningjin County, Dezhou City, Shandong Province.

Q:What is a LVL?

A:Laminated veneer lumber (LVL) is a structural product manufactured from thin peeled veneers of wood glued with a durable adhesive with the grain running parallel to the main axis of the member.its products are widely used in packaging, construction,furniture and other fields.film faced plywood for concrete formwork construction

Q:What are the advantages of LVL?

A:High strength-to-weight ratio – more than 40 stronger than solid sawn products.

High design values for bending, stiffness and shear strength.Resists shrinking, warping, splitting and checking.No defects to cut out and less waste on the job.Ordinary nail assembly – installs as easily as ordinary lumber. film faced plywood for concrete formwork construction

Q:What are the features of fumigation-free wood?

A:What are the features of fumigation-free wood?LVL Board is a special material for exporting wood packaging. It has the characteristics of no fumigation, high strength, high toughness, good stability and accurate size.

Q:Why choose yelu?

A:The company has 2 sub-plants, covering an area of 60,000 square meters, and 12 advanced production lines. It can produce a maximum size of high-grade plate,9.6 meters length, 1.5 meters width and 300 mm thickness. With annual output of 80,000 cubic meters.

LVL 스캐폴드 보드, H20 빔, I 조이스트, 필름 직면 합판

LVL 스캐폴드 보드, H20 빔, I 조이스트, 필름 직면 합판